Traceable Environmental Rope – NS 9415 approved anchoring and mooring rope

Selstad launches NS 9415-approved anchoring and mooring rope

Developed in collaboration with Brisk Aqua Supply and RePlast – traceability and circularity in practice

Selstad is launching a new NS 9415-approved anchoring and mooring rope for the aquaculture industry. The rope is developed and produced in Norway and combines documented strength and quality with full traceability and circular handling, based on the same principles underpinning the Traceable Environmental Rope concept.

The product is the result of a close and focused collaboration between Selstad, RePlast, and Brisk Aqua Supply, where each party contributes its expertise across the value chain.

Collaboration from concept to finished solution

The initiative originated from Brisk Aqua Supply, which identified the market need and contributed to development through close dialogue with customers and partners. Selstad has been responsible for development, production, and formal approval of the rope, while RePlast has contributed by recycling used rope into new plastic granulate. The finished anchoring and mooring rope is supplied to the market through Selstad and Brisk Aqua Supply.

Full traceability – integrated into the rope

The rope is equipped with an integrated identification film running through its entire length, documenting:

Manufacturer

Owner and user

CE documentation and product data

This provides full transparency and verifiability throughout the entire lifecycle, from production and use to return and recycling.

NS 9415 approved – ready for operational use

Approval in accordance with NS 9415 confirms that the rope meets applicable requirements for strength, quality, and documentation for use in anchoring and mooring systems in aquaculture. The solution is suitable for both new installations and upgrades of existing facilities.

Circular value chain – less plastic and lower climate impact

When the rope is taken out of service, it enters an established return scheme. The material is recycled by RePlast into new granulate, which is then used by Selstad in the production of new ropes. This establishes a fully Norwegian, closed-loop system with:

Reduced demand for virgin plastic

Less plastic leakage into the environment

Documented environmental and climate benefits

An important step for Norwegian aquaculture

The launch marks an important step in combining technical quality, traceability, and sustainability in critical infrastructure for the aquaculture industry.

Brisk Aqua developes and launches new Skeleton lice screens

A technological and commercial breakthrough for the aquaculture industry

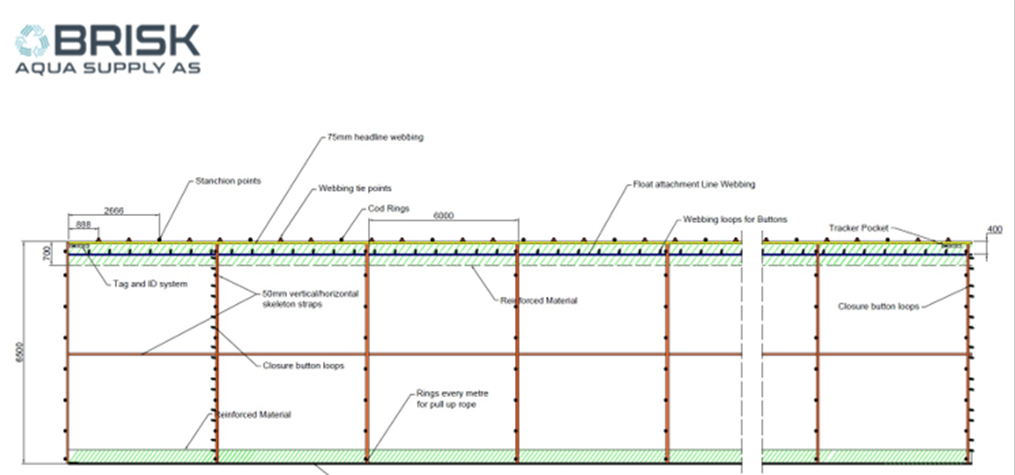

The Brisk Aqua Skeleton lice screen has been developed to address some of the most significant challenges associated with traditional lice screens: short service life, high wear, limited control, and unnecessary environmental impact. The solution combines a new structural design, improved material selection, digital traceability, and an integrated service model.

Strength and service life

The Skeleton structure distributes loads more evenly across the entire screen, reducing point stress and deformation, and providing substantially higher structural strength than conventional solutions. Combined with correct handling and service, the target service life is 5–8 years, compared with a typical 1–3 years for standard lice screens.

Gentle material selection – reduced abrasion and microplastics

PVC has been removed from contact zones and replaced with a soft, smooth, yet highly durable fabric. This results in:

Significantly less abrasion against the net

Reduced wear on both the lice screen and the net cage

Lower risk of microplastic emissions

Improved interaction between equipment during operation

The result is longer service life for both the screen and the net, and a lower overall load on the farming installation.

Full traceability and control

All Skeleton lice screens are digitally tracked via ABAX and combined with traceable environmental ropes. This provides full visibility of:

Where each screen is located

Where it has been deployed

History of washing, service, and repairs

For customers, this enables better control, simplified reporting, and more efficient planning, including reuse of screens between sites. For Brisk Aqua, it provides the basis for efficient logistics, faster turnaround times, and higher asset utilisation.

Integrated service – predictable performance over time

Skeleton lice screens are delivered with a mandatory service agreement through Brisk Aqua Service. The service setup ensures:

Gentle washing with no measurable wear

Regular inspection and repairs

Documented follow-up throughout the entire service life

This is critical to achieving long service life, stable functionality, and predictable operations.

Sustainability and circularity

The combination of extended service life, reduced plastic use, lower microplastic emissions, and full traceability results in a solution that is genuinely more sustainable and well aligned with increasing requirements for documentation, producer responsibility, and circular economy principles.

Commercial value

Although the Skeleton lice screen is designed for a significantly longer service life, the price difference compared with traditional lice screens is relatively limited. When considering total lifespan, reduced wear, improved utilisation, and lower replacement frequency, the solution delivers substantially higher total value over time.

In summary

The Brisk Aqua Skeleton lice screen represents a technological and commercial breakthrough, with documented advantages in strength, service life, traceability, and sustainability, supported by a scalable business model that combines product and service.

Brisk Aqua Service achieves Eco-Lighthouse certification

In 2025, Brisk Aqua Service AS achieved Eco-Lighthouse (Miljøfyrtårn) certification for its Øksfjord branch. The certification represents an important step in the company’s continued efforts toward structured sustainability, documented environmental management, and further professionalisation of operations.

Eco-Lighthouse is Norway’s most recognised environmental management certification scheme, requiring systematic work across areas including energy, waste, climate impact, HSE, and internal control.

For Brisk Aqua Service, the certification entails, among other things:

Documented environmental management and traceability

Clear objectives and measures to reduce climate and environmental impact

Systematic monitoring of waste, energy, and resource consumption

Enhanced quality in operations and reporting

The company handles large volumes of ropes and lice screens and has established documented solutions for material and energy recovery in collaboration with approved partners. These initiatives contribute to increased circularity and a reduced environmental footprint across the value chain.

The Eco-Lighthouse certification forms part of Brisk Aqua Service’s long-term strategy for sustainable growth and continued development as a supplier to the Norwegian aquaculture industry.

Environmental management efforts are also being extended to other branches, and the certification provides an important foundation for meeting stricter customer requirements and aligning with international standards.